News

PTFE tape is replacing the PTFE spray in the certain fields

发布时间 : 2018-09-29 浏览次数 : 次

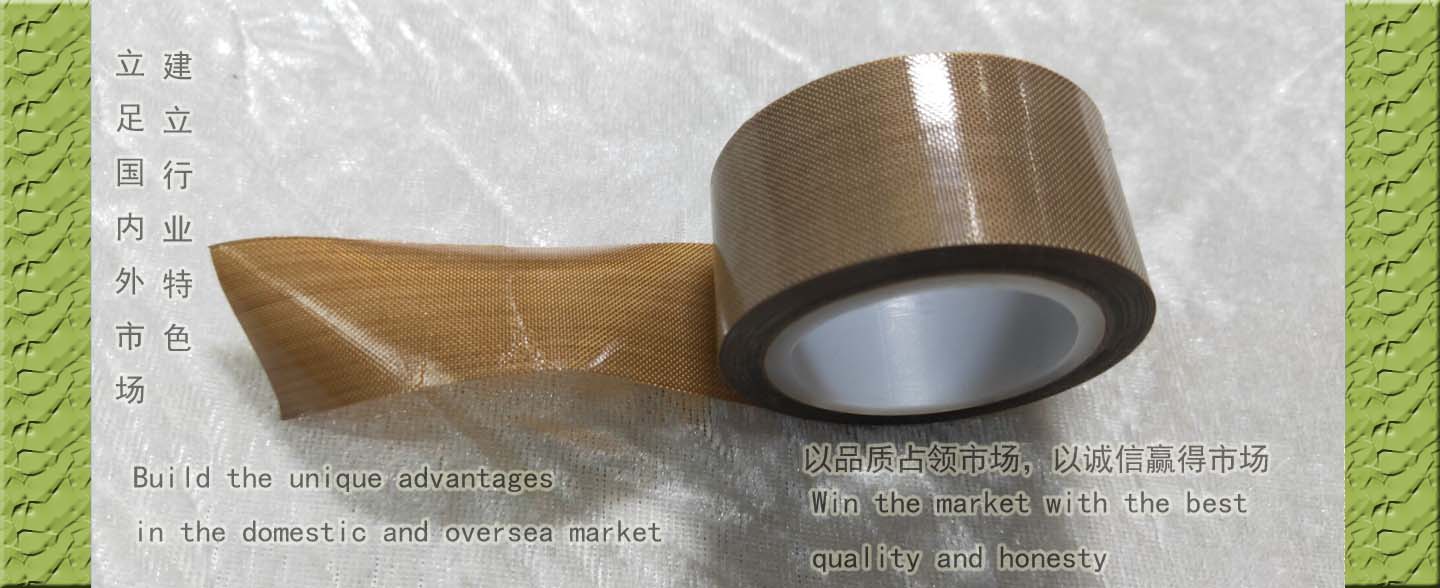

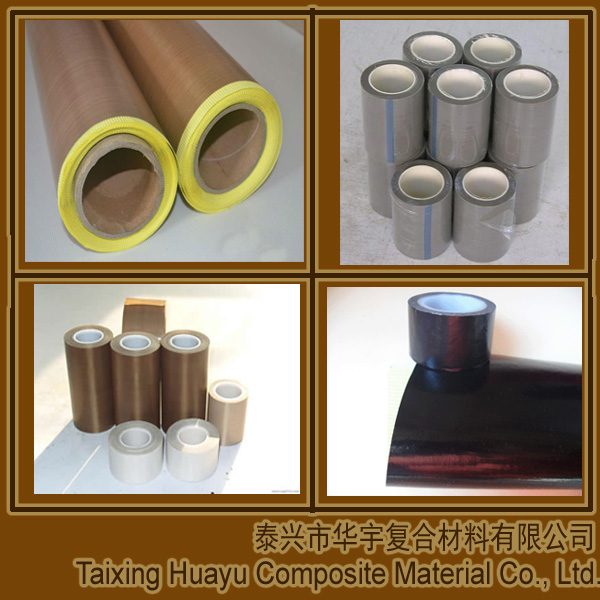

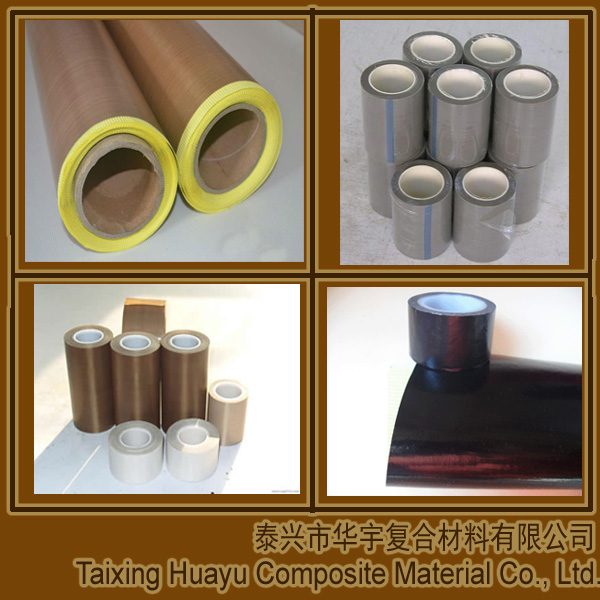

PTFE glass cloth tape in PTFE tape is mainly used to replace part of the spraying process. It is easy to operate and simple to install. It only needs to tear the yellow release paper on the back side and directly stick it to the object. The surface is ok, without any damage to the machine and extending the life of the machine.

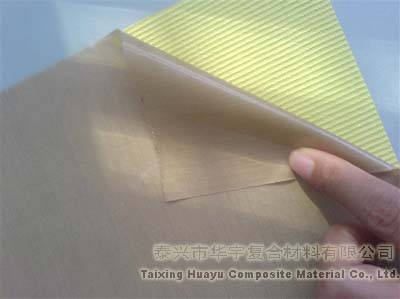

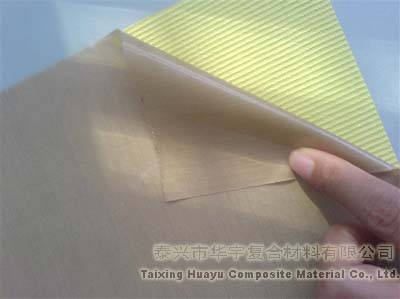

Release paper and tear open picture as shown:

Production process: high-quality glass fiber cloth impregnated with PTFE emulsion, one side after special treatment, the other side maintains its smooth surface.

Use process: tear off the yellow release paper - the surface with the glue is attached to the surface of the roller, rubber roller, etc. - tear off the tape directly when replacing

Note: Before cleaning, check the surface to be treated to ensure that the surface is clean, smooth, flat and dry.

The surface of the tape and the roller is freely separated. As long as the gluing process is standard, the adhesive will not peel off, no residual objects will adhere to the surface, and the replacement is convenient. The tape is small in size and light in weight, and can be transported by ordinary express. The cost per replacement is low.

The amount of PTFE emulsion is the main cost. PTFE glass cloth tape is impregnated with a layer of glass fiber cloth. The impregnation is generally not more than 3 times, so the unit cost is very low.

The main costs of PTFE spraying include PTFE emulsion cost, spray processing cost, transportation cost and maintenance cost. The operation process is cumbersome and the process is complicated. Each spraying cost is high, the machine life is shortened, and the tangible loss is large.

The spray emulsion is integrated with the surface, slightly scratched, and re-sprayed. The cost of the above is re-running back and forth, and even the last machine is directly damaged by multiple sprays. PTFE emulsions are used in large quantities and the unit cost is quite high.

Therefore, in many cases, PTFE tape is gradually replacing the traditional spraying process by virtue of these advantages.

Release paper and tear open picture as shown:

Production process: high-quality glass fiber cloth impregnated with PTFE emulsion, one side after special treatment, the other side maintains its smooth surface.

Use process: tear off the yellow release paper - the surface with the glue is attached to the surface of the roller, rubber roller, etc. - tear off the tape directly when replacing

Note: Before cleaning, check the surface to be treated to ensure that the surface is clean, smooth, flat and dry.

The surface of the tape and the roller is freely separated. As long as the gluing process is standard, the adhesive will not peel off, no residual objects will adhere to the surface, and the replacement is convenient. The tape is small in size and light in weight, and can be transported by ordinary express. The cost per replacement is low.

The amount of PTFE emulsion is the main cost. PTFE glass cloth tape is impregnated with a layer of glass fiber cloth. The impregnation is generally not more than 3 times, so the unit cost is very low.

The main costs of PTFE spraying include PTFE emulsion cost, spray processing cost, transportation cost and maintenance cost. The operation process is cumbersome and the process is complicated. Each spraying cost is high, the machine life is shortened, and the tangible loss is large.

The spray emulsion is integrated with the surface, slightly scratched, and re-sprayed. The cost of the above is re-running back and forth, and even the last machine is directly damaged by multiple sprays. PTFE emulsions are used in large quantities and the unit cost is quite high.

Therefore, in many cases, PTFE tape is gradually replacing the traditional spraying process by virtue of these advantages.